| Product Name | Price | Delivery | Qty |

|---|---|---|---|

| Autoclave PRESSUREWAVE 60L Cód.18001060 |

€292.00 €175.30 |

||

| Autoclave PRESSUREWAVE 80L Cód.18001080 |

€344.65 €206.80 |

||

| Autoclave PRESSUREWAVE 100L Cód.18001100 |

€471.83 €283.10 |

||

| Autoclave PRESSUREWAVE 150L Cód.18001150 |

€669.24 €401.60 |

||

| Autoclave PRESSUREWAVE 200L Cód.18001200 |

€781.55 €624.85 |

Product Description

PressureWave™ - Challenger vessels are especially suited for a wide range of applications including booster systems, thermal expansion, irrigation systems and water hammer (hydraulic shock) absorption.

The PressureWave™ - Challenger Series is comprised of a virgin polypropylene liner with an FDA certified high grade butyl diaphragm. This diaphragm is fixed to the inner wall of the reservoir through a steel ring. The brass air valve, sealed with a threaded O-ring cap, prevents air leakage. Water enters the Vessel through a patented stainless steel connection. Both the diaphragm and the liner are reinforced in the areas of greatest wear, thus increasing the useful life of the tank. All internal parts, including the air valve, are rounded to prevent diaphragm puncture in extreme conditions. The water connection has a unique air/water seal that makes the container completely airtight and makes maintenance unnecessary.

Externally, the almond-colored polyurethane paint finish over an epoxy basecoat provides hundreds of hours of UV and salt spray protection.

PressureWave™ Autoclaves undergo multiple quality tests at every stage of the production chain to ensure the structural integrity of every vessel manufactured. PressureWave™ Vessels represent the best investment option and are the best pressure vessels available on the market today.

CHARACTERISTICS

Designed with a single fixed diaphragm.

Certifications: NSF standard 61, CE/PED, WRAS, ACS, ISO-9001 and Gost.

Patented stainless steel 1" water connection.

Virgin polypropylene liner.

Polyurethane paint finish on epoxy base.

Air valve cover with leak-proof O-ring seal.

Exhaustive quality tests at all stages of production.

They don't require maintenance.

Maximum working pressure: 10 bar

Maximum working temperature: 90ºC

Factory preload: 3.2 bar (60 - 150 liters)

All connections are stainless steel

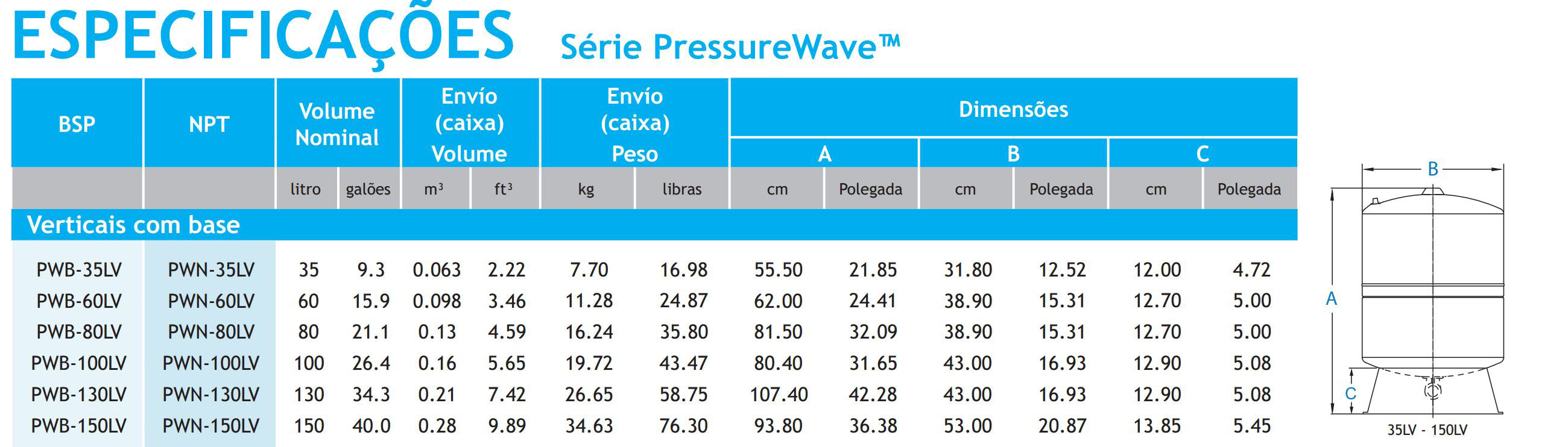

Specification